Vision systems have numerous scientific and industrial applications.

Among the documented experiences of SIDeA are:

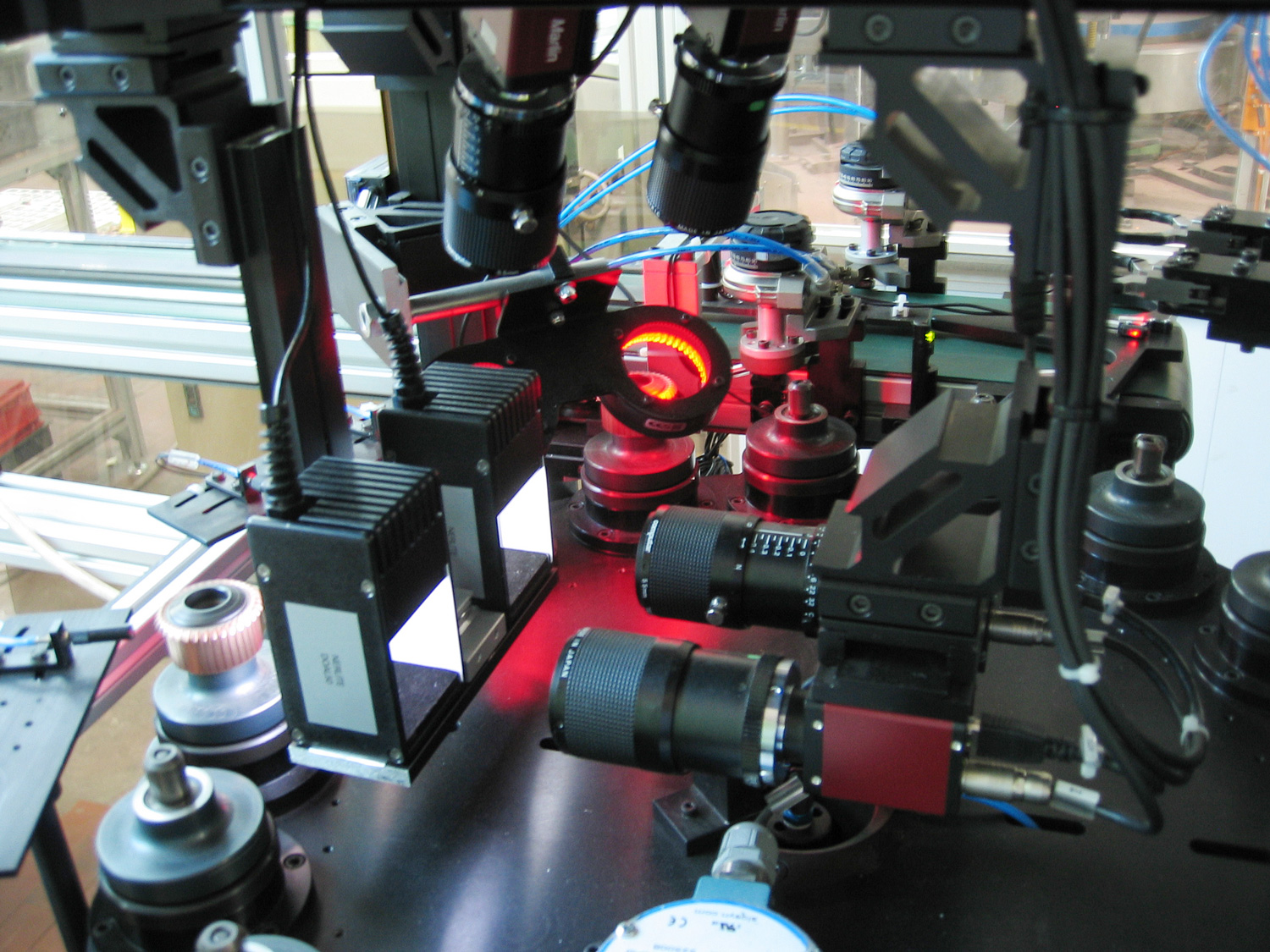

Image Acquisition and Analysis – Machine Vision

Machine Vision is an increasingly established technology in the industrial and manufacturing sectors for activities such as automatic inspection, process control, and robot guidance in automated production lines. However, it also finds applications in other fields such as medical analysis.

The Machine Vision process starts with the acquisition and analysis of images through cameras, optical systems, and sensors. The acquired data is then processed using image processing algorithms and artificial intelligence to extract relevant information, such as quality control or compliance of products, lines, shapes, or dimensions.

SIDeA designs and provides customized Machine Vision systems based on the specific needs of the client’s activities, within the context of plant or equipment modernization projects with a 4.0 focus.