A testing bench is a system designed for accurate and reliable validation of products or subassemblies. This system is applicable across various industries including manufacturing, electronics, aerospace, and more.

SIDeA specializes in crafting custom testing benches tailored to product specifications and client needs. These benches include an array of measurement tools, computerized control systems for intricate and repeatable tests, and dedicated testing equipment.

Additionally, SIDeA can develop and integrate interface hardware such as data acquisition cards or specialized communication devices, ensuring an efficient and secure testing environment.

Specifically, SIDeA offers:

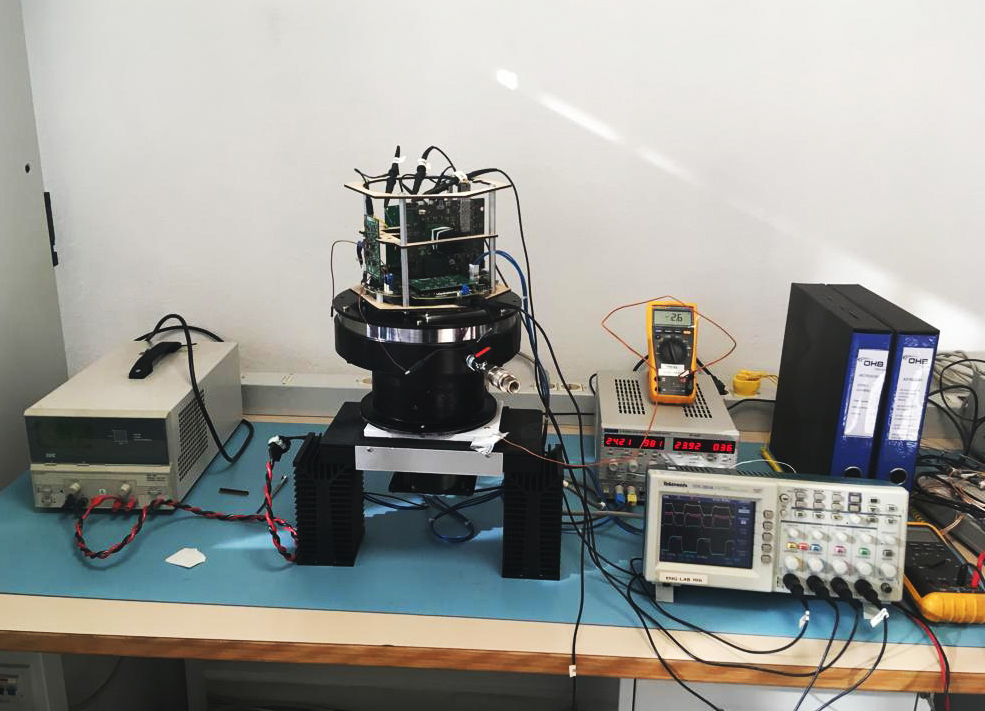

Test benches for Avionics Subsystems

Avionics subsystems include a wide range of components such as sensors, actuators, displays, processors, communication modules, and onboard computers. These components gather information about the aircraft and its surroundings, process it, and transmit it to the flight crew.

Avionics subsystems are essential for ensuring the safety and efficiency of aircraft. They undergo rigorous testing to ensure reliable operation under all possible flight conditions.

The expertise acquired by SIDeA in the Aerospace and Defense sector is reflected in the development of various finished components. These range from specialized interfaces to individual devices and extend to complete test benches and dedicated systems for testing avionics components and systems within aircraft.

Among the documented experiences of SIDeA:

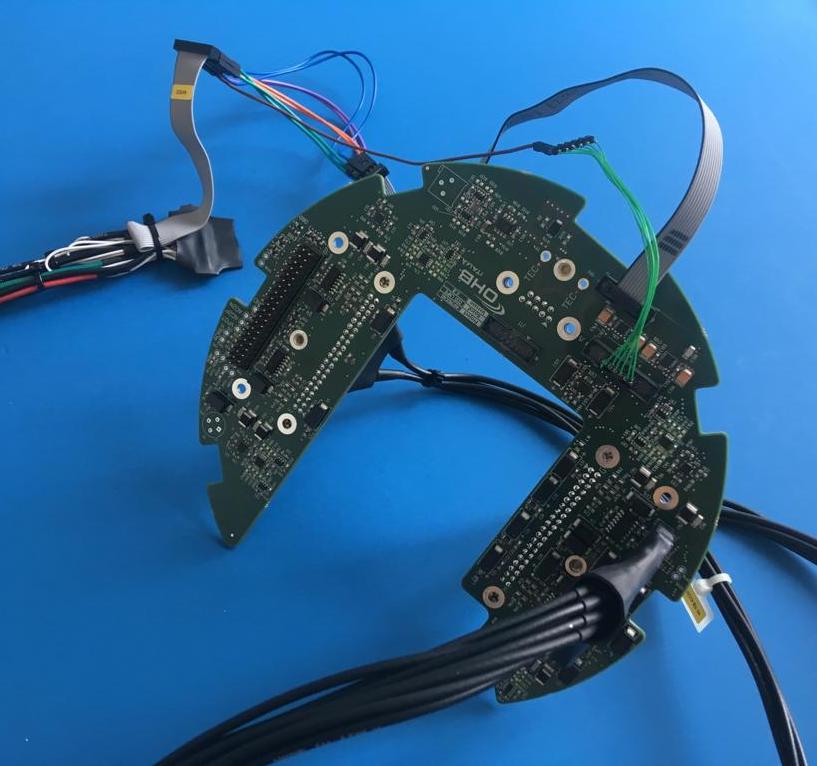

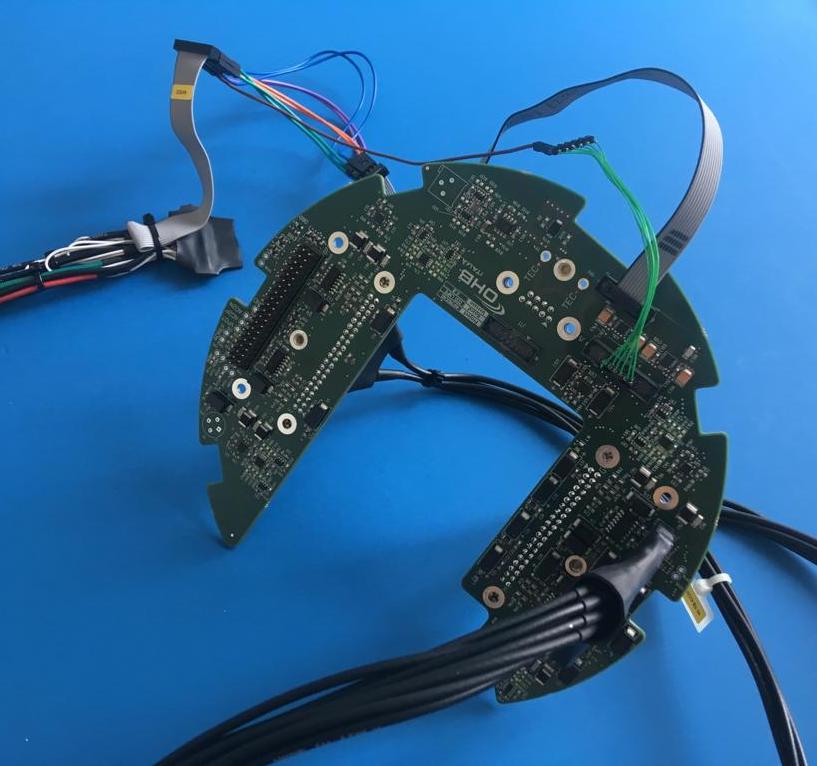

Automatic Test Equipment for Electronic Boards

Automatic Test Systems for Electronic Boards (ATE), also known as Automatic Test Equipment, are specialized devices designed for conducting comprehensive testing of electronic boards.

ATE systems are extensively applied in a broad array of industries, encompassing electronics, automotive, aerospace, and other sectors reliant on electronic boards. SIDeA specializes in the design of automatic test systems for electronic boards. Our systems cater to testing a diverse spectrum of components, including microprocessors, integrated circuits, printed circuit boards, memories, signal converters, and sensors.

ATE systems employ advanced methodologies, including functional testing, boundary scan testing, continuity testing, and other techniques. These methods are instrumental in detecting potential malfunctions and irregularities within the components, ensuring the reliability and performance of electronic boards.

Automatic Test Equipment for Electronic Boards

Automatic Test Systems for Electronic Boards (ATE), also known as Automatic Test Equipment, are specialized devices designed for conducting comprehensive testing of electronic boards.

ATE systems are extensively applied in a broad array of industries, encompassing electronics, automotive, aerospace, and other sectors reliant on electronic boards. SIDeA specializes in the design of automatic test systems for electronic boards. Our systems cater to testing a diverse spectrum of components, including microprocessors, integrated circuits, printed circuit boards, memories, signal converters, and sensors.

ATE systems employ advanced methodologies, including functional testing, boundary scan testing, continuity testing, and other techniques. These methods are instrumental in detecting potential malfunctions and irregularities within the components, ensuring the reliability and performance of electronic boards.

Appliance Testing Systems

Household appliance testing systems are designed to assess a wide range of equipment, such as washing machines, refrigerators, dryers, dishwashers, and other household appliances.

These systems employ an array of automated tests to verify the operation of appliances under various usage conditions. This includes safety testing, functional testing, durability testing, and other methods to ensure products adhere to safety and quality requirements and standards.