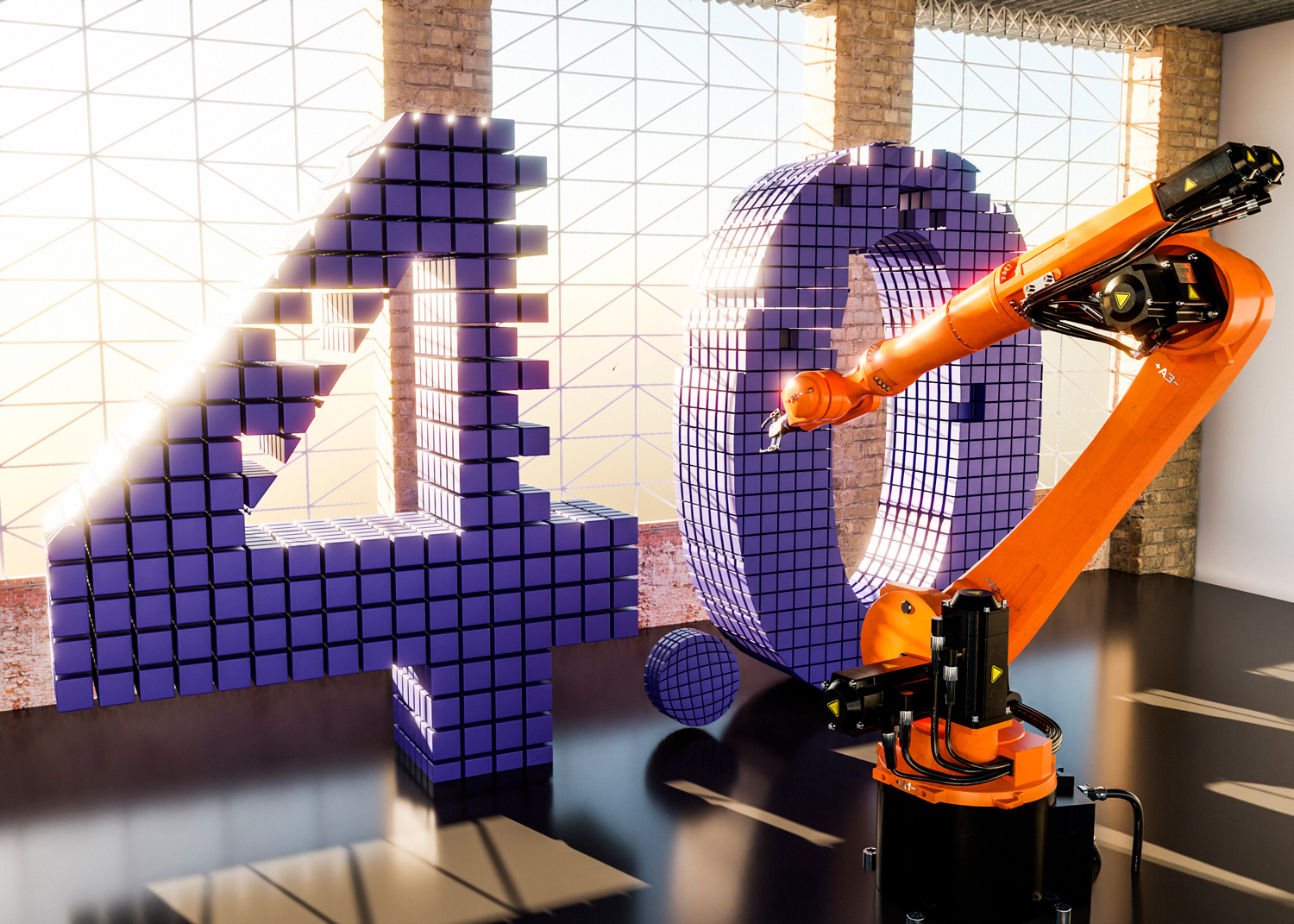

Industry 4.0 represents the fourth industrial revolution, characterized by the application of advanced digital technologies to transform production processes. It is based on the integration of intelligent systems, Internet of Things (IoT), data analytics, artificial intelligence (AI), and automation.

Industry 4.0 offers benefits such as efficiency, cost reduction, mass customization, and the creation of new business models.

Having tools that support optimization between products, processes and people is the decisive step taken in smart manufacturing, where introduction of new technologies into production ecosystem improves efficiency and flexibility of the entire manufacturing industry.

Data, after being collected and processed by sensors placed on machines, are used to enhance existing processes, ensuring greater efficiency, yield, and safety.

In general, a digitized and intelligent factory ensures:

Maintaining a competitive advantage is crucial for any company, both domestically and internationally, and Industry 4.0 is completely transforming the industrial landscape as we know it.

In this scenario, thanks to its experience and specific know-how in the field, SIDeA plays the role of preferred partner, starting from the process of identifying essential requirements, assisting in the selection of appropriate tools, all the way to the realization of the suitable solution.

Benefits for Companies

The key transformation that triggers the shift towards factory digitalization sees businesses evolving into Smart Factories, where digitalization and technology are at the core of the production chain.

This transformation entails that all components, both physical and virtual, are interconnected and capable of operating in a coordinated manner. Moreover, it ensures that available resources are utilized efficiently and effectively.

Within a smart factory, machines are equipped with sensors that capture specific data. All data is then integrated with information collected from ERP, supply chain, customer support services, and other business systems, thus enhancing and expanding on previously gathered insights. Analyzing the collected data based on specific parameters enables the enhancement of the entire production process.

This transition marks the beginning of the fourth industrial revolution, propelling businesses towards a technological mix of automation, information, connectivity, and programming.