A test station is a system designed to automatically perform measurements and checks on devices or products, without the need for human intervention. These functions are essential in manufacturing industries to verify and qualify the functionality and quality of products during the production process.

An automatic test station can be designed to carry out a wide range of tests, such as mechanical strength tests and electronic performance tests. Automatic test stations can also accurately record and analyze test data, enabling companies to quickly identify and address any product quality issues.

SIDeA specializes in designing and developing automatic test stations, in-line test systems, and hardware-in-the-loop systems (HIL).

Hardware-in-the-Loop Systems (HIL)

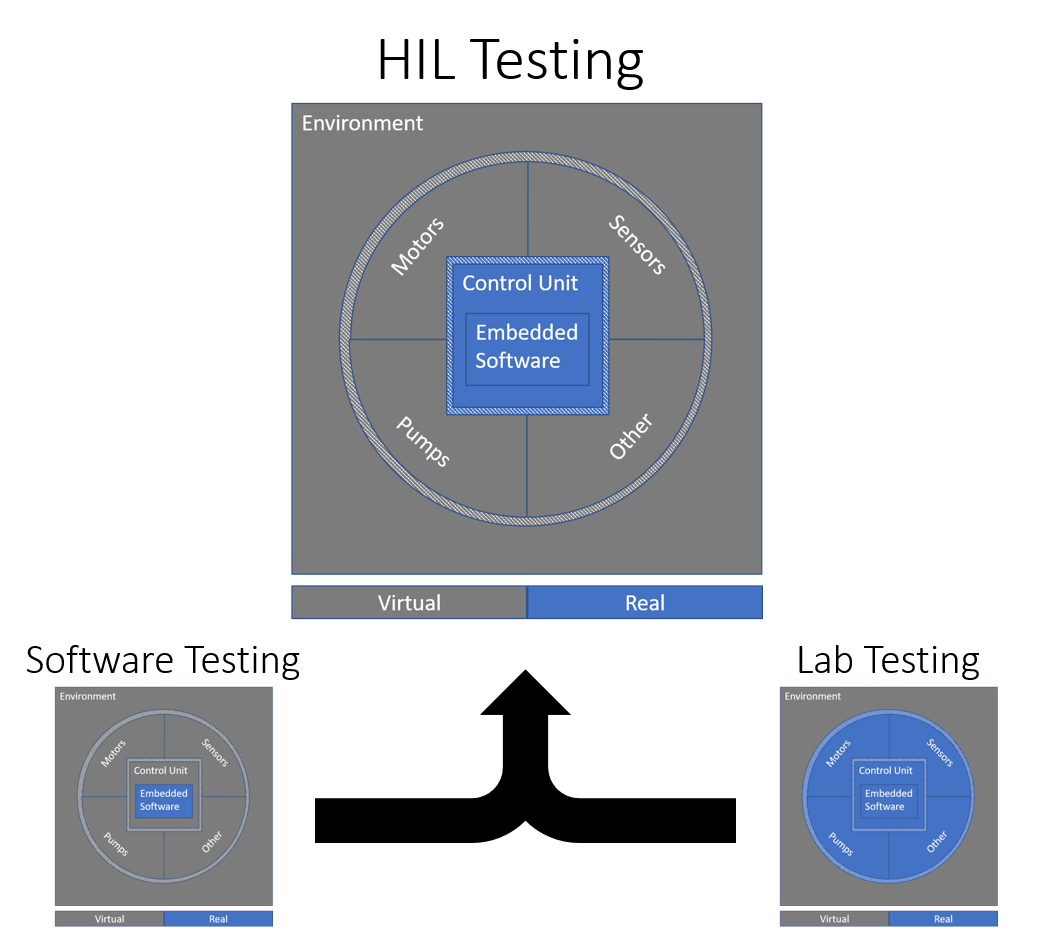

A Hardware in the Loop (HIL) system is a type of testing system that combines software simulation with real-world hardware. The HIL system employs software simulators to emulate the behavior of the system under testing, while the actual hardware is integrated into the testing setup. The primary objective of an HIL system is to verify the interaction between the software and hardware within a complex system, all within a safe and controlled test environment.

Through HIL simulation, software development no longer requires a physical setup to write and test code. Moreover, tests can involve simulating larger versions of a facility or overloading simulations that could potentially damage hardware.

SIDeA has designed and developed hardware in the loop systems for companies operating across various market sectors.

Typical applications of HIL systems include:

Automatic Test Equipment

SIDeA designs and provides Automatic Test Equipment (ATE) stations developed by integrating professional commercial instrumentation with a computerized system that enables complete control.

SIDeA’s automatic test station systems are developed as an interconnection of predefined modules, among which include:

The modular hardware structure is mirrored in the accompanying software structure. Procedures are implemented using LabVIEW and advanced test managers like TestStand.

Automatic Test Equipment

SIDeA designs and provides Automatic Test Equipment (ATE) stations developed by integrating professional commercial instrumentation with a computerized system that enables complete control.

SIDeA’s automatic test station systems are developed as an interconnection of predefined modules, among which include:

The modular hardware structure is mirrored in the accompanying software structure. Procedures are implemented using LabVIEW and advanced test managers like TestStand.